Sustainable Construction

Objective

Deliver low carbon, resource efficient, whole life solutions

Goals

Collaborate across our value chain to promote sustainable construction

Provide industry leading guidance and solutions that optimise whole life performance

Innovate low carbon, sustainable products, services and solutions

“Accelerating the journey to net zero carbon has never been higher on the agenda. We recognise that we, as a leader in the sector, have a key role to play in shaping our industry’s approach to sustainability and in delivering sustainable construction methods and products.”

Brian Kent, Tarmac’s National Technical Director

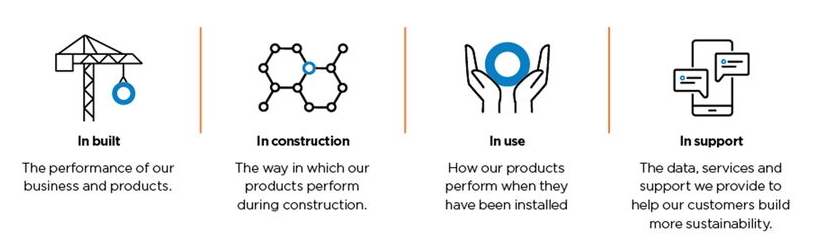

The products, services and tools we provide are of significant benefit to our customers and clients when it comes to designing and building more sustainably, especially when engaged early, in advance of a project commencing. We are committed to delivering value to our customers and clients through application of our four ‘ins’ model to help them take a whole life cycle approach to meeting the challenge of creating a more sustainable built environment.

Highlights

Our approach to solutions

To help customers create a more sustainable built environment we focus our approach across four areas:

In built

Continuously improving the sustainability performance of our business and of our products is a key element of sustainable construction. We do this by ensuring our raw materials are responsibly sourced, we are protecting the environment and enhancing biodiversity through excellent site stewardship, reducing carbon, water and waste, increasing recycled content and improving transport efficiency.

In construction

The way in which our solutions perform can make a significant contribution to improving the sustainability of the construction process, whether it is being safer, faster, more flexible or reducing waste. We continue to research and deliver new innovative products to assist our customer’s projects.

In use

How our products perform once they have been installed is a crucial part of their life cycle and can have a profound impact on the sustainability of a building or infrastructure asset. For example, our solutions can improve sustainability during the in-use phase of an asset by enhancing durability, reducing maintenance, and delivering energy and carbon savings. Designing them so that they can be efficiently re-used at the end of their current life can also contribute towards a circular economy.

In support

The information, services and tools we provide are of significant benefit to customers when it comes to designing and building more sustainably, especially when engaged early, in advance of a project commencing.

Sustainable collaboration

Our commercial team continues to work with the business to develop relationships with key national customers that help us deliver significant projects across the country.

One example of these strategic relationships is our formal collaborative business relationship with Costain, who we have worked closely with over many years. Through sharing common values, goals and ambitions we have delivered more for customers. This collaboration allows us to offer a greater carbon saving, use less materials and reduce waste sent to landfill.

In 2021, we launched a joint document on our employee intranet to showcase our work with Costain, raise awareness and encourage involvement across Tarmac. The success of this relationship is highlighted by it being accredited to ISO 44001:2017 Collaborative Business Relationship Management Systems.

Clean construction: unlocking net zero

Tarmac teamed up with Infrastructure Intelligence to undertake a unique piece of research – Clean construction: unlocking net zero – which delivered essential insights from industry decision makers about the key challenges being faced on the journey ahead to net zero.

The full report can be accessed here: https://www.tarmac.com/clean-construction-report/

The online event, A collaborative approach to sustainable, innovative construction, provided a multi-channel opportunity to discuss the UK road network, build awareness of Tarmac’s view of the transition to net zero, as well as debate the practical steps Government and industry must take to drive clean construction and deliver net zero by 2050.

Tarmac speakers including Dr Martyn Kenny, Sustainability Director, and Brian Kent, National Technical Director, discussed the findings of the company’s latest clean construction research and the results of trials into anti-ageing asphalt technology – a collaboration with Shell and Total Energies to develop a range of new materials to extend the lifetime of roads. Over 20 technical talks featured throughout the event to provide attendees with details of innovative Tarmac materials currently available, as well as those under development.

Tarmac Guide to Sustainable Road Building

As part of our sustainability strategy, we launched a new online framework designed to support those involved in specifying and maintaining the UK’s crucial network of roads and highways: the Guide to Sustainable Road building. The guide offers advice including using lower carbon materials, reducing waste and incorporating recycled materials to create more sustainable roads.

Cutting carbon and keeping the roads moving

Tarmac’s contracting business is the UK’s leading supplier of highways surfacing, operating a fleet of 124 surfacing and planing machines, which lay around 3.5 million tonnes of asphalt each year. Applications range from resurfacing of motorways, roads and pathways, to the construction of car parks, runways and running tracks. Warm mix asphalts can deliver CO2 savings of between 8-12% compared to conventional materials, with no compromise on performance. As this solution is used at a lower temperature, it also cuts the amount of time needed to set, thereby minimising resources required, including labour and cost, which helps to maximise returns from budgets and reduces disruption to local communities.

tonnes of warm mix asphalt laid in 2021

Innovative construction solutions

Rubber modified asphalt

Our strategy is built on whole life thinking and pushing boundaries to develop innovative solutions to create sustainable buildings and infrastructure. In 2021, we became the first company in the UK to secure recognised industry approval for our rubber modified asphalt, which uses recycled end of life car tyres for use on the strategic road network.

It is now possible to reuse the rubber from up to 500 waste tyres for every kilometre of highway resurfaced, depending on the thickness of the road. This new solution has been used in road networks across the country saving thousands of tyres from going to waste. We helped Leicestershire County Council deliver greener roads with the biggest supply to date of this new rubberised asphalt.

tonnes of asphalt supplied – using 3,300 waste car tyres

tonnes of material containing innovative bitumen laid in Northamptonshire

AgeSafe Bitumen

Working in partnership with Shell, we have trialled a new type of bitumen called AgeSafe. This bitumen is specially designed to resist aging due to oxidation, a key process that over time leads to pavement failure in conventional road surfacing products. Over 200 tonnes of material containing the new bitumen has been laid and is being closely monitored, with the aim that this will enable more durable, longer lasting roads.

Luminescent concrete

Toptint Glow is our unique, decorative concrete that uses light sensitive chippings to help illuminate areas such as footpaths, cycle paths and other pedestrian areas. It uses recycled composite luminescent chippings that absorb UV radiation during the day and radiate it at night as visible light. It is a high performing and long-lasting concrete, that also helps to illuminate dimly lit areas without installing additional lighting, delivering energy and carbon savings.

Carbon footprints

There is a growing need to transition to net zero carbon, especially following the Government's target to achieve a 68% reduction in greenhouse gas emissions by 2030 (from 1990) and ‘net zero’ by 2050. Tarmac is committed to helping achieve this aim through managing and reducing the carbon footprint of our operations and products and by helping our customers to do the same. We are increasingly delivering low carbon materials, responding to carbon related enquiries and supporting customers to select the lowest carbon option for their projects and achieve their carbon targets. In 2021, we responded to 890 carbon footprints requests.

Looking forward

As a leading supplier of sustainable construction materials, we know we have a key role in enabling a sustainable built environment. In 2022, we will continue to collaborate across the value chain to promote sustainable construction and provide industry leading guidance. We will help our customers and clients understand how to use our products to build more sustainably through our Building Sustainability virtual event, which will demonstrate new approaches to procurement across the supply chain and discuss the implementation of innovative materials, processes, and strategies that will drive the sector forward towards net zero carbon.

We have also announced our UKREiif net zero hub and partner, where we will be hosting discussions and debate over the course of the three-day event in May, as well as showcasing our own game-changing activity which is helping to lead the transition to a more sustainable and resilient construction industry.

To continue delivering low carbon, resource efficient, whole life solutions which support our customers and clients to transition to a circular economy and to be net zero by 2050 we will be conducting ultra-low carbon concrete demonstrations and will launch a new suite of Tarmac Environmental Product Declarations.